Deep Dive: Theory of Constraints: Manufacturing

I’m going to start with the context I first learned about all this stuff in.

Manufacturing!

I, of course, know nothing about manufacturing and have 0 first hand experience manufacturing anything. I know nothing about machines used for manufacturing. Nothing about “plant floors”. I grew up as off-shoring was increasingly common. Of course, it does seem that manufacturing is ebbing and flowing to and fro from shore to shore. All manufacturing is not going to China for the rest of time. It will come and go for the rest of time.

In my previous post, a resource I mentioned I’ll be pulling from for these posts is, The Goal, by Eliyahu Goldratt, the book that first shined a light for me, and for many, on “flow” and the theory and principles underpinning it. It takes place at a nameless manufacturing plant in a nameless town in middle America. It begins with a conversation about the impact of robots on the productivity of the main character’s manufacturing plant, Alex Rogo. Rogo is telling his old physics professor Jonah that he’s heading to a conference to talk up his plant’s use of robots.

Thanks for reading Constrained Flow! Subscribe for free to receive new posts and support my work.

Jonah immediately begins curiously poking holes in Rogo’s concept of productivity and even his fundamental assumptions about the raison d’etre of his little manufacturing plant. “What is the goal of your little plant?” He basically asks. From there we embark on a thriller of a story to learn, as readers, if Alex and his managers can learn enough from Jonah’s worldview to save their little plant.

Goldratt is teaching us readers a lot in this book. At a high-level, I see 3 major frames he wants to impart to readers.

How education could/should work / How people really actually learn.

The Theory of Constraints and the principles that underpin “flow”

How to apply #2 or, a Process of Ongoing Improvement (the book’s subtitle)

These posts/newsletters are about flow and constraints and how to apply these ideas to the world and our lives around us, basically, #2.

Because I want to apply this theory in a number of contexts, I’m going to try to frame the theory not as it’s presented to communicate #1 above but for ease of comparison to other contexts.

First, let’s start simply with the terms.

Flow - What is flowing in this context?

Finished products manufactured by the plant that customers demand and trade money for.

Constraints - Are there constraints? If so, what are they?

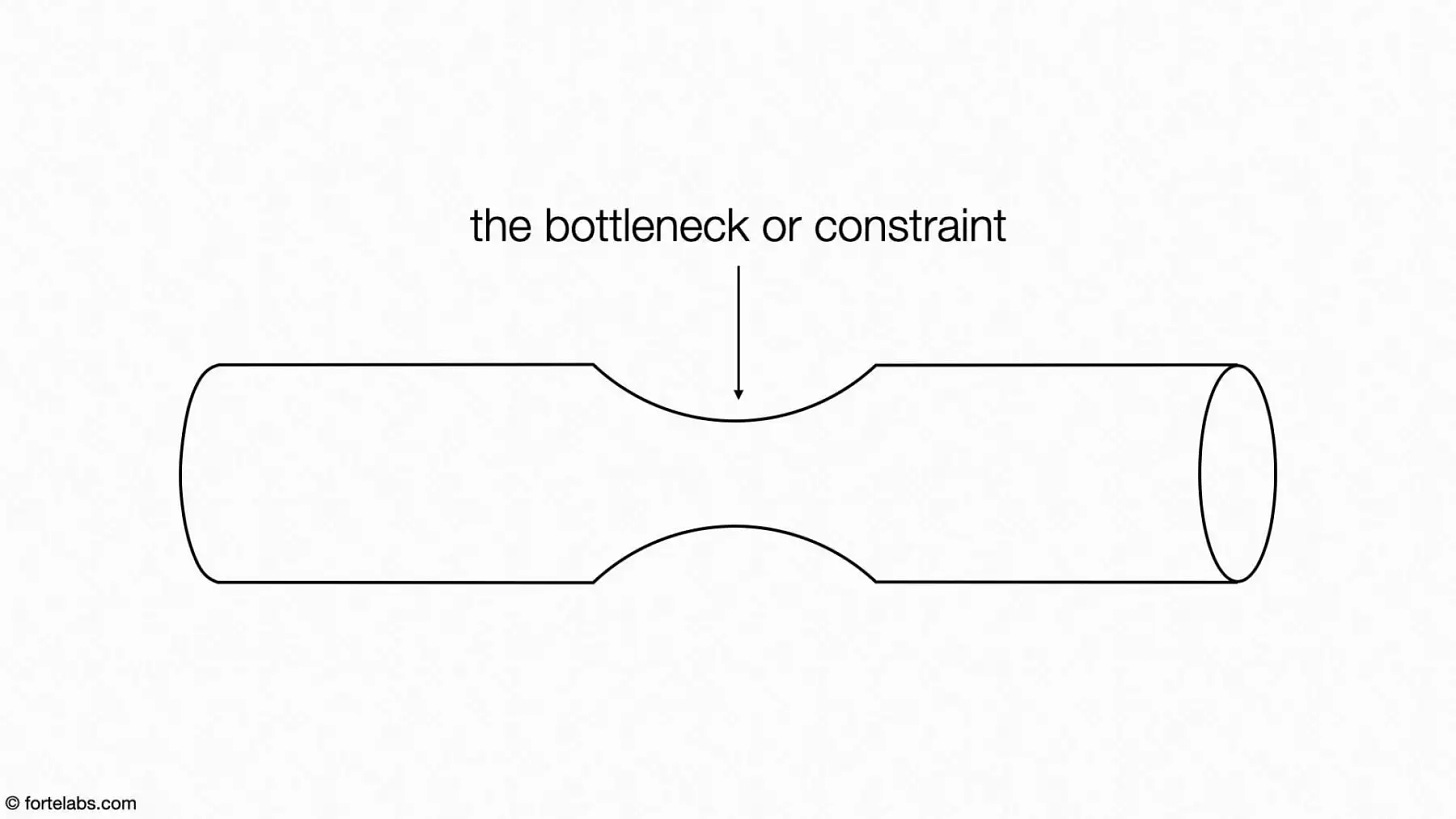

The manufacturing plant cannot manufacture infinity products in an instant to then sell to customers. There is a manufacturing process that takes a non 0 amount of time.

The constraints for much of the book are two work centers/machines/processes. Later the most important constraint is sales/marketing.

The Goal - What is the raison d’etre for this manufacturing plant? Why would one setup a manufacturing plant?

In one way of thinking about it, to serve customers. One might be simply motivated to fill customers’ needs, but more often than not, one wants to also benefit from serving customer needs. In the book The Goal, at least, this is the answer to the big ultimate frame. The Goal is to make money. The way I see it though, is if one is making money, customers’ needs are being met. The money and the customer service are two sides of the same coin.

One of the key insights that Goldratt communicates through his character Jonah is that, as one choreographing events of the manufacturing plant, one must balance flow not with capacity, but with demand. And you want to “manage” that flow so that the flow is smooth (balanced) so that there are no major adverse affects of the constraints/bottlenecks.

Another, sillier, context I’ve noticed the Theory of Constraints in is pouring liquids from bottles. Water or wine, it doesn’t matter, 9 times of out of 10, when we start pouring a full bottle we hear a “glug”. Several in fact. The glugs are the flow of the liquid hitting the literal neck of the bottle. Rogo, in the beginning of The Goal, has lots and lots of glugs all over the place. Late orders, piles of inventory, warehouses of unsold finished goods, expediting extremely late orders on a regular basis that demands major heroics and burnout from employees as well as expensive overtime. Lots and lots of glugs.

As Rogo and his team begin to apply the Theory of Constraints they manage to smooth out the glugs so that flow is balanced with market demand. They do so so well that they even have to go to sales and marketing to let them know they can meet greater demand if sales and marketing can find it. This to me is the real promise of applying this theory, greater value added without the extreme burnout. Or put more simply: thriving instead of just barely surviving with your head barely above water.